Unlock the power of MSC Simufact Forming 16, the industry-leading software for simulating forming and forging processes! Imagine a world where you can virtually test your manufacturing ideas refining them to perfection before even touching a single piece of metal. With MSC Simufact Forming 16’s 3D functionality, you’ll get a realistic glimpse of how your tools and parts interact, revealing every nuance and subtle detail.

What’s So Amazing About MSC Simufact Forming 16?

This software is a game-changer for anyone involved in manufacturing. It takes the guesswork out of your process by considering all the critical factors that impact your results, including:

- Precise machine kinematics: See how your machines move with unmatched accuracy, replicating real-world behavior.

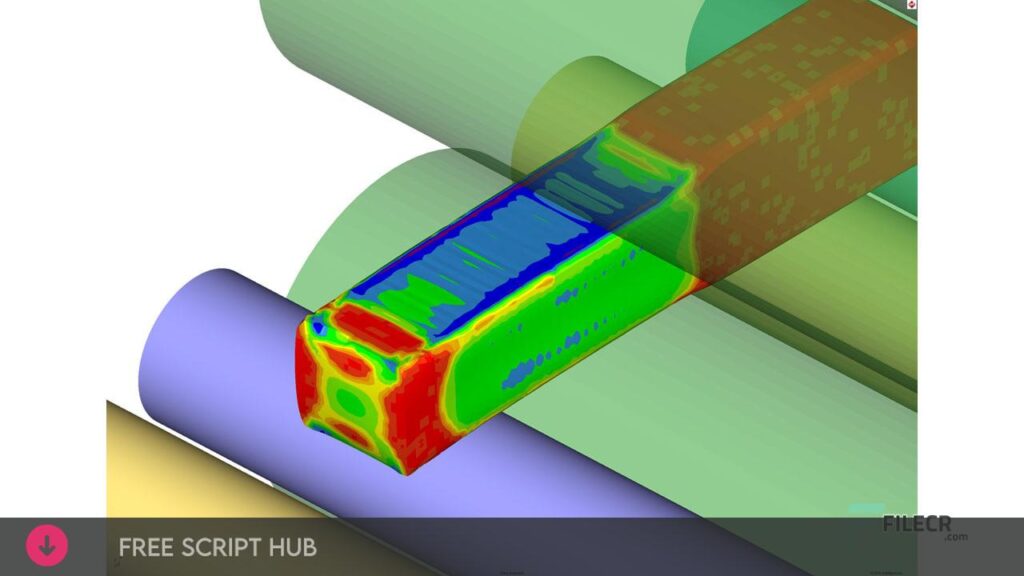

- Complex material behavior: Understand how materials respond under pressure, temperature and other critical conditions.

- Realistic tool-part interactions: Witness the intricate dance between your tools and the forming parts, with detailed friction and contact analysis.

- Predictive bending and folding: See how your parts might bend or fold under stress, preventing costly mistakes before they occur.

- Thermal considerations: Explore the impact of heat on your entire manufacturing process from initial heating to the final result.

What Can You Do with MSC Simufact Forming 16?

This software offers an impressive range of modules, catering to your specific needs. The core module Forming Hub, is your gateway to cold forming and hot forging simulations. But that’s not all! You can also explore a vast array of other processes, including:

- Sheet metal forming: Bend, shape, and mold your sheet metal components with precision.

- Rolling: Simulate rolling operations with ease understanding how the process affects material properties.

- Ring rolling: Create intricate rings and circular components with accuracy and efficiency.

- Open die forging: Design and refine your open die forging processes with greater control and understanding.

- Heat treatment: Simulate heat treatment processes, ensuring optimal material properties and durability.

- Mechanical joining: Visualize and analyze the effectiveness of various mechanical joining methods.

And if that wasn’t enough, there are additional modules designed to enhance your workflow, including stress analysis, performance optimization, and seamless CAD integration.

PC Requirements

Windows 10 or later

64-bit processor

8 GB RAM

10 GB of free hard disk space

**Free Download Full Version** | **Download for Free** | **MSC Simufact Forming 16 Crack + Patch**